| Soil Conductivity Material | ||||

| Product ID | Product Name | Size | Weight | Content |

| LG-4L.20.01 | Soil Conductivity Material | 330*250 mm | 10.7 kg | Bucket |

| LG-4L.20.02 | Soil Conductivity Material | 320*320*150 mm | 10 kg | Bag |

The soils resist the electric current very differently depending on their geographical location and minerals in their composition. Especially in rocky regions where the soil layer is low and gravel sand is dense, the depreciator of the soil is high and consequently its permeability is very low.

At the heart of the grounding system, the aim is to transmit the electric current to the soil as soon as possible. In grounding systems where the resistance to the soil is high, the back reflection of the non-discharge of electricity constitutes great damages first in terms of life and then in terms of property safety. For this purpose, the grounding resistance of communication systems, especially with its operation and parafudr grounding, must be less than 1 Ohm in accordance with the regulations.

Chemical mixtures are the only method of increasing conductivity where grounding resistance is high. International Institutions also recommend the use of chemical mixtures in such soils that reduce soil permeability resistance. But when such chemical mixtures are mixed into the soil, they should have properties that will not change the natural structure of the soil, pollute underground and aboveground water sources, in short, do not disturb the ecological balance of nature.

Liva Soil Conductivity Material (TIM) is a domestic product that is imported and manufactured from abroad as a result of long studies that have exceeded two years. Chemical analysis of our product has been carried out and it has been determined by experiments that it gives much better results (providing 10-20 times better conductivity) than its market counterparts in applications.

You can apply Liva Soil Conductivity Material (TIM) with all kinds of soils in all types of terrain conditions.

Liva Soil Conductivity Material’s Effect on Soil

• Reduces soil resistance by increasing existing soil conductivity.

• Ensures that the conductivity of the applied soil remains stable for many years.

• Chemical or physical changes of the soil in applications do not reduce the activation.

• There will be no change in their own qualities in the meantime.

• Reduces the risk of freezing by 20%, especially in regions that are very cold in winter.

• In order to be more

efficient, there is no need to add any other substances (Salt, Coal dust, etc.) and there is no need to keep the application area constantly wet or damp.

Advantages of Liva Soil Conductivity Material

• Due to its high conductivity, it provides serious advantages in the consumption of grounding electrode or strip materials.

• Minimizes costs in reducing grounding resistance.

• Shortens the labor process to reduce grounding resistance.

• Water in the soil is not adversely affected by their potential.

• It does not create an acidic reaction with salt-based chemicals found in the soil.

• It creates a reaction with any chemicals in the soil and does not cause galvanic corrosion.

• Provides ease of operation and on-site application with its original packaging.

• Gloves and dust masks that are needed during application are in the packaging.

• Easy to apply.

CE Certificate: Tim (Soil Conductivity Material) has received “CE” European Conformity certificate as of February 23, 2009.

SOIL CONDUCTIVITY MATERIAL APPLICATION PRINCES

| Application With Grounding Electrode; | ||||

|

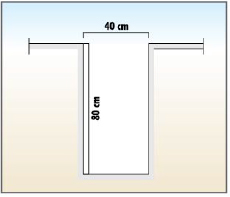

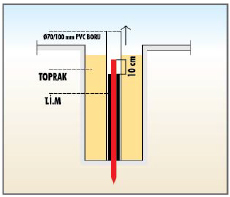

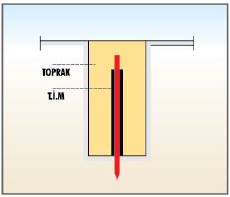

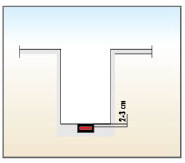

A hole is dug in the depth of 70 to 80 cm and in the width of 30 to 40 cm. in the place of application of the earthing electrode. | |||

|

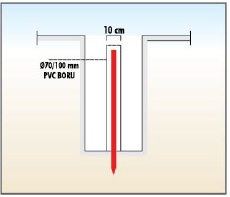

The electrode is driven in this hole as it is placed 10 cm. Left open from the ground and a PVC pipe 70 or 100 mm. In diameter is enclosed around the rod. | |||

|

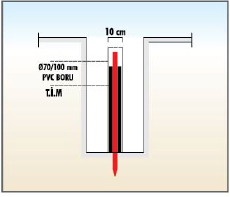

After the electrode is centered in the pipe, it is filled with TIM as the electrode is left open 10 cm. from the top. | |||

|

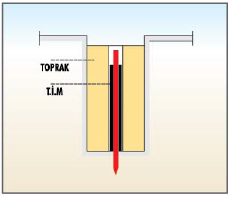

This part (electrode hole] is covered with soil except PVC pipe. | |||

|

The PVC pipe enclosed around the outer part of the electrode is detached from its place by with drawing it upwards. | |||

|

The soil in the hole is compressed in order that the contact of soil with TIM around the electrode becomes better. | |||

|

NOTE: The local grounding resistance of laid-out grounding conductor is measured with grounding measurement device. In case the grounding resistance comes out high, the canal length may be expanded or a grounding system may be installed with a second canal apart from 5 m. This application is repeated until finding appropriate grounding resistance. |

||||

| Application With Tape Earthing | ||||

|

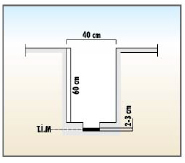

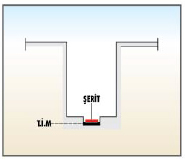

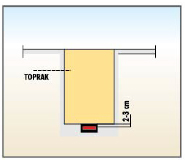

A canal is dug 70 to 80 cm. in depth and 30 to 40 cm. in width in soil where earthing conductor or tape is applied. | |||

|

Serilen TİM iizerine çıplak topraklama iletkeni yada şerit döşenir. | |||

|

On the layered TIM, bare earthing conductor or tape is laid. | |||

|

TIM is laid on the floor of the canal 10 cm. In width and 2 to 3 cm. thick. | |||

|

The TIM laid on the conductor is covered with soil completely. (Don’t use sand.) NOTE: Local grounding resistance of the grounding conductor, which is laid down with the grounding measuring instrument, is measured. If the grounding resistance is high, the canal length can be extended or a second channel can be installed with an interval of 5 m. This application is repeated until proper grounding resistance is found. |

||||

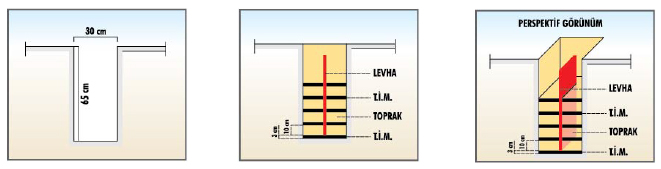

| Application With Sheet |

|

| A hole is dug 60-70 cm. in depth and 30-40 cm. in width in the place where the grounding conductor or band is applied. TJM is laid on the floor of the canal 3-4m cm. thick. The conductive tape is placed on the laid-out TJM vertically. Soil is laid 10 cm. thick on the TIM.TIM is laid 3-4 cm. on the soil again. This application is repeated 4-5 times as it is 3-4 cm TIM and 10 cm. soil. The local grounding resistance of laid-out grounding conductor is measured with grounding measurement device. In case the grounding resistance comes out high, this application may be repeated along the tape upwards. Dependent on the soil resistance, widening of the use surface and increasing of the use of TIM reduces soil resistance. When the appropriate resistance value is captured, the hole is closed with soil completely. (Don’t use sand.) |

| NOTE: If it is desired, Liva Soil Conductivity Material may be applied by diluting it in consistency of cement plaster in a suitable container. At the end of the application, PVC pipe must be taken out surely. |

WhatsApp us